HARDHITTER | The Process of Building a Heavy Truck Charging

Station: A Detailed Guide and Experience Sharing from

Planning to Construction

In the current era of rapid development of new energy,

the ownership and penetration rate of electric heavy

trucks are continuously increasing, and the energy

supply mode is undergoing changes, leading to a

significant increase in the demand for heavy truck

charging stations.

Building a heavy truck charging station involves

multiple links and professional fields. Each step, from

planning, construction to operation, is crucial. The

following is a guide to the process of building a heavy

truck charging station, incorporating the experience and

suggestions of HARDHITTER, hoping to provide ideas and

useful references for your station building process.

I. Preliminary Planning and Research

1、Market Demand Analysis

The first step is to understand the local heavy truck

ownership . For example, the working hours of mining

heavy trucks are relatively fixed, but they have short

charging intervals and a large demand for centralized

charging; the operation routes of logistics transport

heavy trucks are complex, and charging facilities may be

required along the way and at the destination.

By communicating with local logistics enterprises,

mining enterprises, transport fleets, etc., collect

usage information of heavy trucks, such as mileage,

operation time, parking duration, etc. At the same time,

combined with the local economic development trend and

industrial planning, predict the future growth of the

number of heavy trucks to evaluate the potential

charging demand. Scientifically determine the scale and

service capacity of the charging station to avoid

over-construction or insufficient capacity.

2. Site Selection Evaluation

Traffic Convenience:

It is of utmost importance to select a site close to

highway entrances and exits, intersections of national

and provincial roads, or large logistics parks, ports,

mines and other areas where heavy trucks are intensively

operated. When evaluating traffic convenience, some

specific data can more intuitively reflect the

advantages of the site selection.

Generally speaking, a distance within 5 kilometers from

the highway entrance and exit is an ideal range, so that

heavy trucks can reach the charging station in a short

time after getting off the highway, reducing the empty

driving time and power consumption of vehicles on the

road.

For the site selection of national and provincial roads,

the distance between the charging station and the road

should not exceed 2 - 3 kilometers, and the average

speed of the surrounding roads during peak hours should

not be less than 30 kilometers per hour to ensure that

heavy trucks entering and leaving the charging station

will not cause traffic congestion.

If it is near a logistics park, the straight-line

distance between the charging station and the main

entrance and exit of the park is preferably controlled

within 1 - 2 kilometers to ensure sufficient buffer

space and traffic capacity.

For the site selection around the port, the traffic

capacity of the internal roads of the port should be

considered. Generally, the designed traffic capacity of

the main roads of the port should be able to meet the

flow of at least 100 heavy trucks per hour, and the

distance between the charging station and the loading

and unloading area of the port should not exceed 3 - 5

kilometers, which is convenient for heavy trucks to

charge during the loading and unloading of goods.

In addition, pay attention to the smoothness of the

surrounding traffic and avoid traffic congestion caused

by vehicles entering and leaving the charging station.

You can observe the traffic flow and traffic conditions

of the surrounding roads during peak hours on the spot

and select a location with sufficient buffer space.

Power Supply Conditions:

Communicate with the local power department. Investigate

the capacity and stability of the existing power grid

and understand the future upgrade plan of the power

grid. For heavy truck charging stations with large power

consumption, dedicated line power supply may need to be

considered.

During the initial stage of site selection, evaluate the

feasibility of power access at the alternative sites.

Pay attention to the price policy of the local power

supply. Different regions and power supply methods may

have large cost differences, which have an important

impact on the long-term operating cost of the charging

station.

Land Resources:

According to the planned scale of the charging station,

find a suitable area of land. The nature of the land

must meet the construction requirements. Priority is

given to industrial land or construction land that meets

the planning. Consider the service life of the land and

try to choose a long-term and stable lease or purchase

method to avoid affecting the continuous operation of

the charging station due to land problems.

When evaluating the land cost, in addition to the rent

or purchase price, also consider the possible costs such

as land leveling and supporting infrastructure around

the land. In addition, you can pay attention to the

local government's industrial park planning or land

preferential policies and strive to obtain more

favorable construction conditions.

II. Project Approval and Filing

1、Project Initiation

Writing a project feasibility study report is a

systematic project. When elaborating on the necessity of

project construction, in addition to market demand

analysis, it is also necessary to combine the national

and local new energy development strategies and

environmental protection policies to highlight the

positive significance of the heavy truck charging

station for regional sustainable development.

In the technical scheme part, describe the charging

equipment selection, layout planning, power supply

system design and other contents. For economic

evaluation, consider construction costs, operating

costs, revenue forecasts, etc., including details such

as equipment depreciation, personnel wages, electricity

costs, and charging service fee income.

When applying for project initiation to the relevant

government departments, ensure that the report content

is detailed and the data is accurate, and actively

communicate with the approval department to answer the

questions they may raise.

2、Planning Approval

When submitting the planning and design scheme of the

charging station to the local planning department, in

addition to meeting the basic building and layout

specifications, also pay attention to the coordination

with the surrounding environment.

When planning the charging area, consider factors such

as the turning radius and parking spacing of heavy

trucks to ensure the convenience and safety of vehicle

charging operations. If it affects the surrounding

traffic, it is necessary to provide the corresponding

traffic organization scheme, such as the design of

vehicle entry and exit routes and parking guidance

signs.

3、Power Access Approval

Submit a power access application to the power supply

department. The detailed calculation of power load and

the basis for selecting the access point are very

important. In addition to the expected simultaneous

usage rate of charging equipment and the maximum power

demand, etc., also consider the future expansion demand.

When negotiating the access scheme with the power

department, you can ask whether there is the possibility

of smart grid access, which helps to improve the power

management efficiency and stability of the charging

station. Understand the procedures and time nodes for

handling the power access process and prepare the

relevant materials in advance to avoid delaying the

project progress due to formalities.

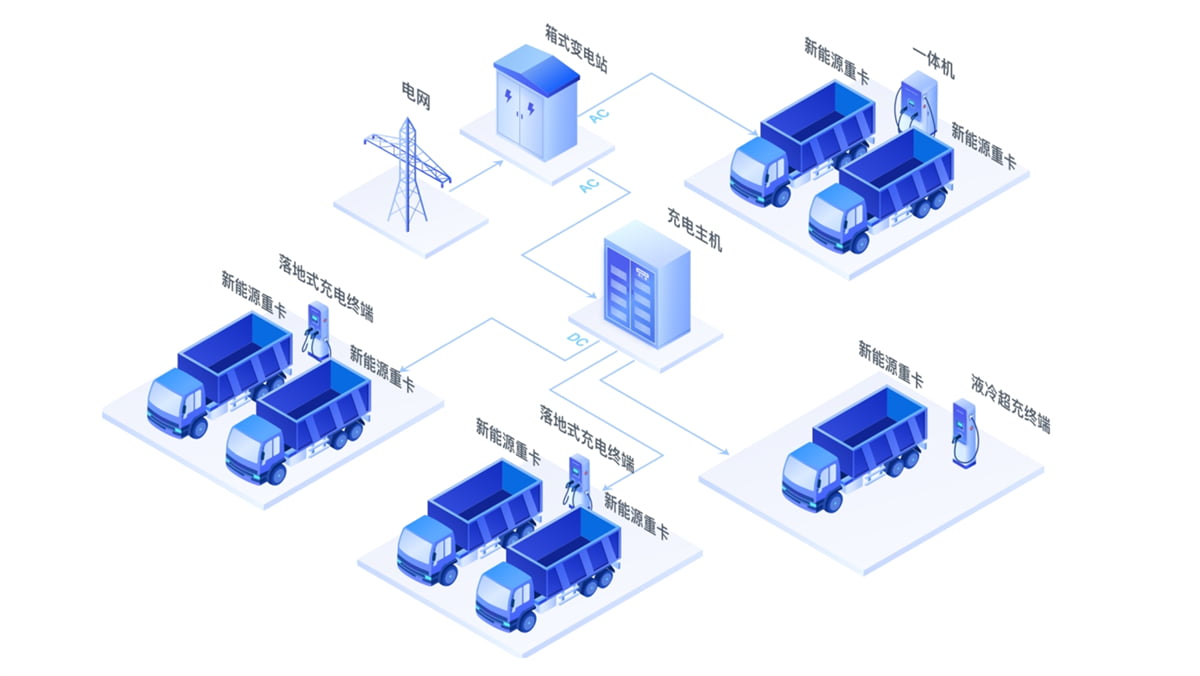

III. Equipment Selection and Procurement

1、Charging Equipment

Heavy truck charging requires high power, and DC fast

charging equipment is the mainstream choice. However,

when selecting a specific model, it should be determined

according to the battery type, capacity of the heavy

truck and the charging time requirements of the

operating enterprise. For example, for some new heavy

trucks with large battery capacity, charging equipment

with a power of more than 300kW may need to be selected.

The compatibility of the equipment is crucial. It is

necessary to ensure that it can be compatible with the

charging interfaces and communication protocols of

various mainstream heavy truck models on the market.

In terms of safety, select equipment with multiple

protection functions, such as overvoltage, overcurrent,

and leakage protection, and it must comply with relevant

international and domestic safety standards.

The degree of intelligence is also a consideration

factor. Charging equipment with an intelligent power

scheduling system can automatically adjust the charging

power according to the power grid load and the vehicle

battery state, improving the charging efficiency and

power grid stability.

It is recommended to test different brands and models of

charging equipment before procurement or refer to the

usage of the equipment in existing charging stations.

2、Auxiliary Equipment

Transformer:

Select an energy-efficient transformer with an

appropriate capacity according to the total power

consumption and peak power load, and reserve capacity

redundancy.

Distribution Cabinet:

The design should be reasonable, able to clearly

distribute power, have overload and short-circuit

protection functions, be easy to operate and maintain,

and a distribution cabinet with an intelligent

electricity meter and monitoring function can be

selected.

Monitoring System:

It should have strong compatibility, stable and reliable

data transmission, be easy to operate and maintain, and

can real-time monitor the charging status, equipment

operation status and environmental parameters and other

information.

Fire-fighting Equipment:

In addition to conventional fire extinguishers and fire

hydrants, consider installing an automatic fire alarm

system and an automatic fire extinguishing system, and

configure them reasonably according to the layout of the

charging station and the distribution of equipment.

IV. Charging Station Construction

1、Infrastructure Construction

Site Leveling:

Use measuring instruments to measure the flatness and

slope of the site (the flatness error is within ±5 cm),

and use mechanical equipment for leveling. If there is a

problem of water accumulation, design a drainage slope

(not less than 0.3% - 0.5%) to ensure that rainwater can

be smoothly drained out of the site and avoid affecting

the normal use of charging equipment and vehicles due to

rainwater accumulation.

Building Construction:

Charging Shed:

Consider the local climate conditions. The height of the

shed roof should not be less than 4.5 meters. Use a

steel structure with a yield strength of not less than

235MPa to build the frame. The shed roof material can be

selected from 0.4 - 0.6 mm thick color steel plate or 6

- 10 mm thick sunlight panel, which can be selected

according to actual needs and budget.

Management Room:

The building area is determined according to the number

of operating personnel and functional requirements (for

example, for 5 - 8 people, the area is 80 - 120 square

meters).

Cable Trench Excavation:

Excavate according to the design requirements. The depth

is generally between 0.8 - 1.2 meters, and the width is

between 0.4 - 0.6 meters. Lay a 10 - 15 cm thick layer

of fine sand as the cushion layer in the trench. After

the cable is laid, cover another layer, and finally seal

it with a cement cover plate or red brick.

2、Equipment Installation and Commissioning

Equipment Installation:

It should be installed by professional electrical

technicians according to the equipment installation

instructions.

Determine the installation position of the equipment to

ensure that there is sufficient safety distance between

the equipment and surrounding objects. For example, the

distance between the charging equipment and the wall

should not be less than 1 meter, and the distance

between it and other equipment should not be less than

0.8 meters to ensure the heat dissipation and

maintenance space of the equipment during operation.

For the fixed installation of the equipment, use

expansion bolts or anchor bolts to fix the equipment on

the ground or foundation platform. The specification of

the bolts should be determined according to the weight

and installation requirements of the equipment. For

example, for charging equipment weighing 500 - 1000

kilograms, generally use M16 - M20 expansion bolts.

When installing the distribution cabinet, place the

distribution cabinet in the appropriate position

according to the design drawings to ensure a reasonable

electrical connection distance between the distribution

cabinet and other equipment, which is convenient for

operation and maintenance. The foundation height of the

distribution cabinet is generally between 0.2 - 0.4

meters to avoid the influence of ground humidity on the

distribution cabinet.

For a medium-sized charging station, install 1 - 2

cameras per 100 - 200 square meters of area, with a

height of 2.5 - 3.5 meters.

Single-machine Commissioning:

Commission each charging equipment to check whether the

working voltage and current are normal. Generally

speaking, the output voltage error of the charging

equipment should be within ±5%, and the current error

should be within ±10%.

Commission the distribution cabinet to check whether the

overload protection, short-circuit protection and other

functions are normal.

Commission the monitoring equipment to check whether the

image transmission of the monitoring equipment is clear

and whether the data collection is accurate.

On-line Commissioning:

After the single-machine commissioning is completed,

conduct on-line commissioning. Simulate the heavy truck

charging process to test whether the charging function,

power distribution, monitoring data transmission and

other functions of the entire charging station system

are normal.

Check the cooperative working capability between

charging devices For example, when multiple charging

equipment charges a heavy truck at the same time,

whether the power can be reasonably allocated to meet

the charging needs of the heavy truck.

Check whether the communication between the monitoring

system and the charging equipment is normal and whether

the monitoring system can real-time obtain the working

status and charging data of the charging equipment.

V. Operation Preparation and Acceptance

1、Personnel Training

Conduct training for operation and management personnel

on charging equipment operation (start, stop, charging

mode selection, fault handling), safety management

(electrical, fire-fighting, emergency escape knowledge),

and customer service (communication skills, complaint

handling). You can invite technical experts from

equipment suppliers and professional training

institutions for training and conduct assessment after

the training.

2、Operation Preparation

Formulate detailed and operable operation management

systems. The charging standard should comprehensively

consider the cost and market conditions and comply with

the price regulations. The business hours should be

determined according to the local heavy truck operation

time. Formulate emergency response plans (for equipment,

power failures and safety accidents), and prepare

operation materials such as a charging card management

system and an invoice printer.

3、Acceptance

Organize relevant departments and experts for

acceptance, including engineering quality (the building

structure and charging facility installation meet the

design and construction standards), equipment

performance (the performance of charging, monitoring,

and fire-fighting equipment meets the standards), and

safety facilities (fire-fighting passages, fire-fighting

equipment, electrical safety measures) acceptance.

Actively cooperate and timely rectify the problems.

Building a heavy truck charging station is a complex and

systematic project that requires careful planning,

strict construction and full preparation. Each link is

interrelated and influential, and any negligence of

details may affect the overall performance and operation

effect of the charging station.

We hope that the above content can provide strong

guidance for you in the process of building a heavy

truck charging station and jointly promote the vigorous

development of the new energy heavy truck industry.

If you want to know more detailed station building

processes and charging pile product information, please

follow us and leave a message for consultation.